navigate through over products

Dura-Tube

overvew

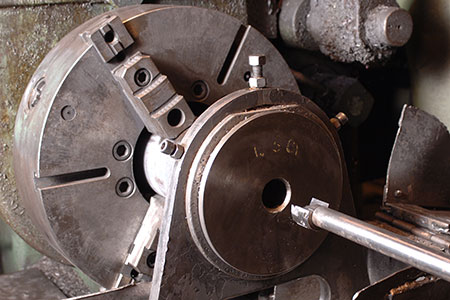

Dura-Tube® is a suite of products, produced either through a proprietary continuous cast or trepan process. Available in a variety of outside diameter (O.D.), inside diameters (I.D.), wall thickness, lengths, and grades, Dura-Tube conforms to ASTM specifications.

Dura-Tube produced using the continuous cast process yields a more concentric tube for optimal machine processing, and a distinct advantage of Dura-Tube compared to centrifugal castings is in the stock removal process.

Most machined parts require boring a hole—a time-intensive machining operation. Dura-Tube products mitigate the need for hole boring, saving time; and since Dura-Tube weighs less than a standard bar, customers will also benefit from lower freight costs, saving time and money. Dura-Tube is perfect solution for Oil and Gas (e.g. slips, bit sleeves), Transportation (e.g. cylinder liners, sheaves, bushings), and Power Transmission (e.g. pulleys, shaft adapters) applications.

Dura-Tube

Dura-Tube is produced in two distinct ways:

Continuously Cast:

- Ideal for thin wall applications (<0.375")

- I.D. and O.D concentricity

- Increased tensile strengths

- Available in O.D.'s < 6.375"

Trepan:

- Ideal for thicker wall applications (>0.375")

- Application requiring an O.D. > 6.375"

- Reduces machining time

- More precise I.D.

Dura-Tube vs. Centrifugal and Static Castings

Royals Metals

- Dura-Tube is an ideal alternative to centrifugal and static castings.

- Dura-Tube is poured from the same quality metal as our continuous cast solid round bars. Chemical, mechanical and microstructure results will be the same as Dura-Bar continuous cast for comparable sizes.

- Dura-Tube outperforms centrifugal and static castings in quality, total machining time, better O.D. clean-up stock, porosity, pattern costs and is backed by Dura-Bar's Zero Defect Guarantee.