navigate through over products

G2 Gray Iron

Overview

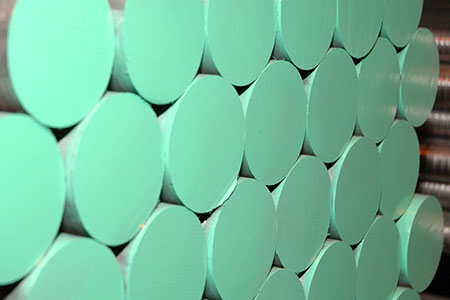

Dura-Bar G2P is a highly pearlitic gray iron containing Type A graphite. It was developed to best suit surface-hardenability applications. G2P is made with a substantial amount of pearlite in the rim. This requires the least amount of stock removal necessary, in order to achieve a heat-treatable surface. Carbon-rich material is forced to the outer edges of the bars. This allows the surface hardening via heat treatment (induction and flame hardening) to be accomplished quickly, consistently, and effectively. To learn more, download the G2P Gray Iron Product Brief.

Microstructure

The microstructure will contain Type VII, A, size 4–6 graphite as defined in ASTM A247. The matrix is fully pearlitic. The edge or rim will consist of Type D, size 6–8 graphite in a matrix that is a combination of pearlite and ferrite. Chill carbides will be less than 5% in any field at 100x and are well dispersed.